- Home

- Information

- Progressive Cavity Pump Rotor and Stator Selection

Shape Selection of the Stator and Rotor

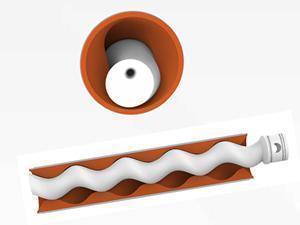

Type A

Short pitch, single head

Thread number of stator and rotor: 1/2

Standard design, stable function, common pump

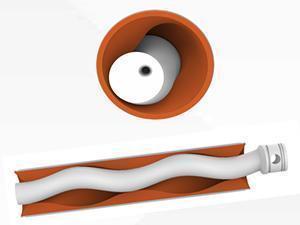

Type B

Long pitch, single thread

Thread number of stator and rotor: 1/2

Suitable for low pressure and big flow

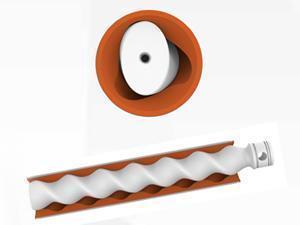

Type D

Short pitch, double thread

Thread number of stator and rotor: 2/3

Suitable for the converying of corrosive media

Type P

Long pitch, double head

Thread number of stator and rotor: 2/3

Suitable for transmission of corrosive substances, low pressure and large flow

| Material | Corrosion resistance | Swelling resistance | Abrasion resistance | High temperature resistance | Temperature range | Application |

| NBR | Satisfactory | Good | Satisfactory | Satisfactory | +110℃ | Petroleum, sewage, food, beverage, chemical, papermaking |

| NBRH | Good | Excellent | Good | Satisfactory | +120℃ | Petroleum, refining and chemical, chemical, sewage |

| EPDM | Good | Poor | Good | Satisfactory | +120℃ | Chemical, chemical agent, papermaking |

| FKM | Excellent | Excellent | Poor | Excellent | +180℃ | High temperature and corrosive medium |

| HNBR | Excellent | Good | Good | Excellent | +170℃ | Petroleum, petrochemical, chemical |

| PTFE | Excellent | Excellent | Poor | Excellent | +230℃ | Corrosive medium(acid, alkali and etc), food and beverage industry |

| Common metal materials | Corrosion resistance | Abrasion resistance | Cl-resistance(ppm) | Suitable medium |

| CRS alloy steel | Common | Common | No resistance | Abrasive mediums without corrosiveness |

| CRS alloy steel with hardening treatment | Common | Excellent | No resistance | Abrasive mediums without corrosiveness |

| SS420 stainless steel with hardening treatment | Satisfactory | Good | No resistance | Abrasive mediums with light corrosivness |

| SS304 stainless steel | Good | Satisfactory | < 100 | Applied in food production, acidic mediums without abrasiveness |

| SS304 stainless steel with hardening treatment | Good | Good | < 100 | Non food applications, corrosive and abrasive mediums |

| SS316 | Good | Satisfactory | 100~2000 | Applied in food industry, acidic mediums with no abrasivness |

| SS316 stainless steel with hardening treatment | Excellent | Excellent | 100~2000 | Non food applications, corrosive and abrasive mediums |

| Duplex SS stainless steel | Excellent | Excellent | 1000~40000 | Corrosive mediums with high Cl- but no abrasiveness |

| Duplex SS stainless steel with hardening treatment | Excellent | Excellent | 1000~40000 | Corrosive medium with high Cl- and abrasiveness |

Note: For all the stators and rotors above, you can choose their type according to your necessary conditions or requirements. Contact us for more details.