Progressive Cavity Pump

Subtor is an expert in the production of progressive cavity pumps. Those types shown below are representative of progressive cavity pumps we have designed based on customer needs.

A progressive cavity pump is a positive displacement pump that features a wide range of applications, including the transportation of mediums within 45% of solid content, and a maximum viscosity of 1 million mPas.

Whether it's sludge, chemicals, adhesives, oil, pulp or yogurt, our progressive cavity pumps can complete the delivery of the needed medium in a quick, efficient manner.

-

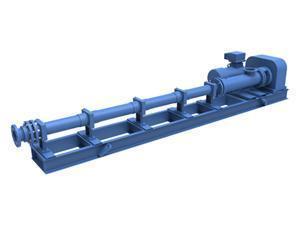

- S Class Progressive Cavity Pump

The S class progressive cavity pump is designed and produced to transport any medium including water.

Food processing plant: delivering honey, maltose, dairy products, beverages, etc.

-

- A Class Progressive Cavity Pump A class progressive cavity pumps produced by Subtor feature a structural design with a bearing black, which can bear a higher axial load than traditional designs. The pump is designed to handle any transport mediums, including water, with a maximum solid content of 45%.

-

- K Class Progressive Cavity Pump The pump body length is shortened to merely 2/3 of standard pumps. This makes the K class pump suitable in shipbuilding, oilfield transportation, offshore platforms or factory applications with tight spaces.

-

- BP Class Progressive Cavity Pump The BP class progressive cavity pump is constructed with a backpack pully drive structure that is designed to reduce the direct impact of axial load forces onto the motor when making equipment adjustments.

-

- V Class Progressive Cavity Pump It is suitable for high pressure pumping applications in oil transportation, particularly for long distance operations. The maximum working pressure of the pump is 72 bar and the maximum flow capacity is 300 meters cubed/hour.

-

- Vertical Progressive Cavity Pump The length of OU vertically class progressive cavity pump can be adjustable, so that the pump can be adjusted to pools or wells of various depths. The rotor and stator stay under the water while operating the pump so that the gear motor does not come into contact with the medium.

-

- Trolley Progressive Cavity Pump The T Class trolley progressive cavity pump is a mobile pumping unit that features casters and handles at the bottom. This makes the pump suitable for pumping conditions in which materials are loaded or unloaded at various stages. The pump can handle any fluid medium with 45% or lower solid content.

-

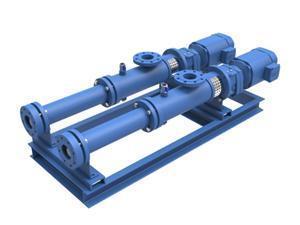

- Skid Mount Progressive Cavity Pump The skid mount progressive cavity pump allows 2-3 pumps to share a common base. This makes the pump suitable for applications in which multiple pumps operating in parallel require a large flow. It can also be applied when a backup pump is immediately necessary in case of fault.

-

- BE Class Progressive Cavity Pump BE class progressive cavity pumps are used for extraction and transportation in containers. They are most often used to transport a variety of liquid mediums, including acids, alkali, solvents, additives, oils and more.

-

- VM Open Hopper Progressive Cavity Pump The VM class progressive cavity pump uses an open hopper device that is suitable for the filling and supply of a variety of viscous mediums. The pump can transport any medium, including water, and it can also transport mediums with up to 45% solid content.

-

- SM Open Hopper Progressive Cavity Pump The SM open hopper progressive cavity pump, is suitable for the conveyance of water and other materials with a maximum of 45% solid content mediums. It features an open suction chamber the makes filing and ration supply of thick mediums convenient, and is easy to move with the use of trundles.

-

- M0 Open Hopper Progressive Cavity Pump

M0 Open hopper progressive cavity pumps feature a coupling shaft equipped with a helical blade that pumps sticky mediums into the chamber.

Starch industry: the conveyance of starch slurry, potato dregs, potato pulp, wheat gluten, paste

-

- M1 Open Hopper Progressive Cavity Pump

An M1 open hopper progressive cavity pump features a rectangular hopper in order to pump the medium. It is suitable for conveyance of thick slurry at a maximum of 18% of solid content, making it suitable for use in the following:

Starch industry: the transmission of starch slurry, potato dregs, potato pulp, wheat gluten, paste

-

- M2 Open Hopper Progressive Cavity Pump An M2 open hopper progressive cavity pump, which has a much larger hopper than other pumps, has the ability to better pump large grained mediums, and is thus suitable for the conveyance of thick mediums with a maximum of 30% solid content.

-

- M3 Open Hopper Progressive Cavity Pump The M3 Open hopper progressive cavity pump is suitable for the transmission of slurry with a maximum of 45% solid content, and is widely used in both environmental protection and the pharmaceutical industry.

-

- Metering Progressive Cavity Pump Metering progressive cavity pumps can be used for automatic, accurate metering applications and gelatinizing systems, including: Lithium battery coating, Automobile seal coating, Industrial electronic component gluing ...

-

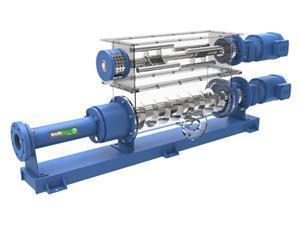

- Multiphase Flow Progressive Cavity Pump With one pipe that simultaneously moves oil and gas, a multiphase flow progressive cavity pump is used specifically to convey the oil/gas mixture, and thus, reduce movement costs. To stabilize the flow output, an automatic constant pressure control system is equipped on the inlet side.

Weifang Subtor as a German Subtor invested company in China, offers wide range of progressive cavity pumps and components. A progressive cavity pump is a type of positive displacement pump, also known as eccentric screw pump. With German supported technology and rich marketing resources, Subtor provides quality PCP pumps with custom solutions for global clients.